Thermal Conductivity & Exceptional Hardness: Tungsten Carbide Spray Nozzles a unique combination of hardness, wear resistance, and high melting point

Tungsten carbide is a remarkable material that has revolutionized various industries with its exceptional properties and versatility.

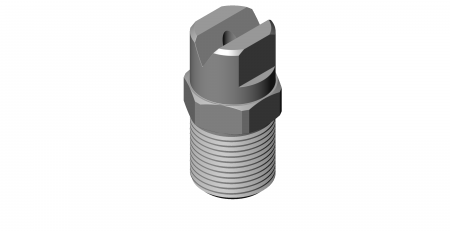

Tungsten carbide spray nozzles are a type of industrial nozzle commonly used in various applications, including coating, cleaning, and cooling processes. They are known for their exceptional hardness and wear resistance, making them ideal for demanding environments where high-velocity or abrasive materials are involved.

Here are some key features and characteristics of tungsten carbide spray nozzles:

Tungsten carbide is a composite material composed of tungsten and carbon atoms. It is extremely hard and has a high melting point, making it suitable for applications that involve high temperatures and abrasive materials.

Tungsten carbide is one of the hardest materials available, exhibiting exceptional wear resistance even in harsh conditions. This property allows tungsten carbide spray nozzles to withstand abrasive particles and extend their lifespan compared to other nozzle materials.

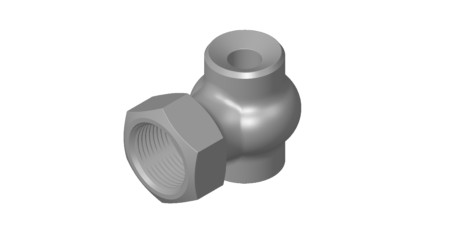

Tungsten carbide nozzles are designed to produce a specific spray pattern, such as a solid stream, flat fan, or conical spray. They also provide precise flow control, allowing operators to adjust the spray angle, droplet size, and flow rate according to the application requirements.

Tungsten carbide exhibits excellent resistance to various corrosive agents, including acids, alkalis, and chemicals. This resistance ensures the longevity and reliability of tungsten carbide spray nozzles, even in corrosive environments.

Tungsten carbide spray nozzles are capable of handling high-pressure systems, making them suitable for applications that require high-velocity sprays or atomization.

Tungsten carbide spray nozzles are used in a wide range of industries, including automotive, manufacturing, steel production, mining, agriculture, and more. They are employed in processes such as metal coating, surface preparation, cooling, cleaning, and dust suppression.

It’s important to note that the design and specifications of tungsten carbide spray nozzles can vary depending on the specific application and requirements. There are different nozzle configurations, sizes, and spray patterns available to accommodate various industrial needs.

.