Durable and Precision in Fluid Dispersion: Brass Spray Nozzles used for Reliable Performance

The properties of brass, such as its corrosion resistance, durability, and machinability, make it well-suited for certain applications

Brass is a metallic alloy made primarily of copper and zinc, with small amounts of other elements added for specific properties. The proportions of copper and zinc can vary, resulting in different types and grades of brass with varying characteristics. Brass is known for its attractive golden appearance, relatively low melting point, and good malleability, which makes it easy to shape and form into various objects.

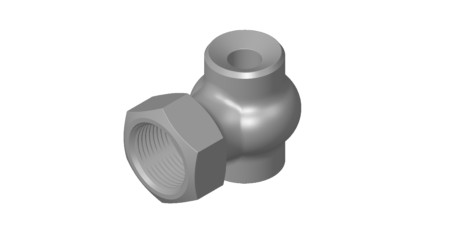

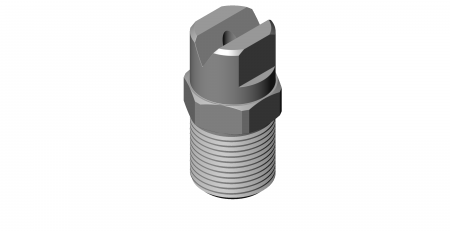

Brass spray nozzles are a popular choice in various industries where controlled and efficient fluid dispersion is essential. These nozzles, made from the brass alloy, offer a combination of durability, corrosion resistance, and precise spray patterns. This article explores the key features, applications, and benefits of brass spray nozzles.

Brass, a copper-zinc alloy, forms the foundation of brass spray nozzles. This alloy is renowned for its exceptional strength and resistance to corrosion, making it suitable for demanding environments. The robust construction ensures that the nozzles can withstand high pressures, abrasive fluids, and harsh chemical agents without compromising performance.

One of the primary advantages of brass spray nozzles is their ability to produce accurate and controlled spray patterns. The machinability of brass allows for intricate designs, enabling manufacturers to customize the nozzle orifice and shape according to specific application requirements. This flexibility ensures that the spray pattern, such as fan, cone, flat, or jet, can be precisely tailored for optimal coverage and efficiency.

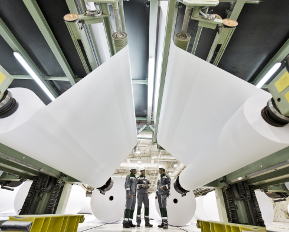

Brass spray nozzles find extensive use in diverse industries. In agriculture, they are employed for irrigation systems, crop spraying, and pest control. Industrial applications include cooling, dust suppression, surface treatment, and chemical processing. They are also utilized in car washes, fire suppression systems, and various cleaning operations. The versatility of brass spray nozzles stems from their ability to handle a wide range of fluids, including water, chemicals, oils, and solvents.

The durability of brass spray nozzles contributes to their resistance against wear and clogging. Their robust construction withstands the impact of particles present in the fluid, reducing the risk of blockages and maintaining consistent spray performance over time. This reliability is particularly crucial in industrial settings, where continuous operation and uninterrupted spray patterns are necessary.

Brass spray nozzles are relatively easy to maintain, requiring routine cleaning to remove any buildup or debris. They can be disassembled for thorough cleaning or replaced if necessary. With proper care, brass spray nozzles have an extended service life, providing cost-effectiveness and reducing downtime due to replacements or repairs.

While brass spray nozzles offer numerous benefits, it’s important to consider specific application requirements before making a selection. In some cases, alternative materials such as stainless steel or plastic may be preferred for their unique properties or compatibility with certain fluids. Factors such as temperature, pressure, chemical compatibility, and spray pattern should be evaluated to ensure optimal performance.

Brass spray nozzles are a durable and reliable solution for precise fluid dispersion in various industries. Their corrosion resistance, versatility, and ability to deliver accurate spray patterns make them a preferred choice for applications ranging from agriculture to industrial processes. By combining the strength of brass with carefully engineered designs, these nozzles contribute to efficient and effective fluid distribution systems.