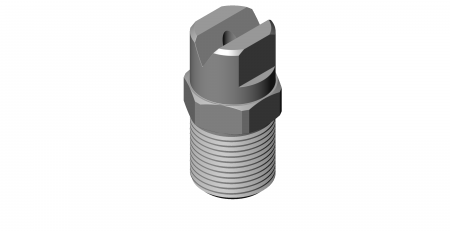

Exceptional Chemical Resistance: PTFE Spray Nozzles with a low coefficient of friction and nonstick properties

Polytetrafluoroethylene (PTFE) is known for its excellent chemical resistance. It is highly resistant to a wide range of chemicals, including acids, bases, solvents, and many corrosive substances.

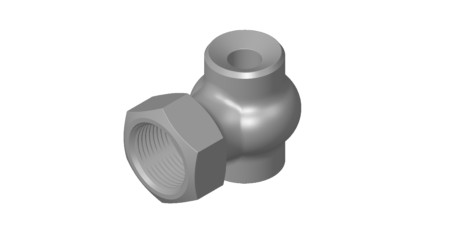

PTFE (polytetrafluoroethylene) spray nozzles are specialized nozzles used in various industries for their unique properties and applications. PTFE is a synthetic fluoropolymer known for its exceptional chemical resistance, low coefficient of friction, high temperature resistance, and nonstick properties. These characteristics make PTFE spray nozzles ideal for handling corrosive chemicals, high-temperature liquids, and materials that tend to stick or cause clogging.

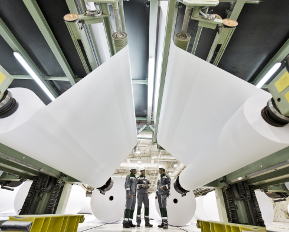

PTFE spray nozzles are commonly used in applications such as:

PTFE nozzles are used for spraying aggressive chemicals, acids, and solvents in industries like chemical manufacturing, petrochemicals, pharmaceuticals, and wastewater treatment.

PTFE spray nozzles are employed in food processing, dairy, brewing, and bottling industries to handle food-grade liquids, syrups, sauces, and cleaning solutions. Their nonstick properties make them suitable for applications involving sticky or viscous fluids.

PTFE nozzles are utilized in painting, coating, and surface treatment processes. They can withstand high temperatures and resist chemicals used in these applications while providing precise and uniform spraying.

PTFE spray nozzles are used for cooling applications in industrial processes and as part of dust suppression systems in mining, construction, and material handling operations.

Fire Protection Systems: PTFE nozzles can be found in fire sprinkler systems and fire suppression equipment due to their ability to withstand high temperatures and resist corrosion.

When selecting PTFE spray nozzles, factors such as spray pattern, flow rate, pressure rating, and compatibility with the intended fluid or chemical should be considered. It’s important to consult with manufacturers or suppliers experienced in industrial spray nozzles to ensure the right selection for your specific application.