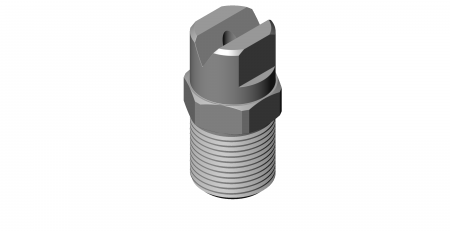

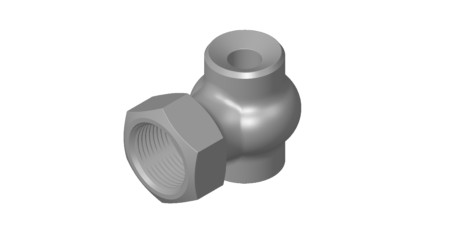

Innovative Spray Nozzles and Cutting-Edge Materials for Precision and Efficiency

Reasons why different materials are used in spray nozzle manufacturing

Different materials are used in spray nozzles to accommodate various requirements and optimize performance in different applications.

Different materials have varying levels of resistance to different chemicals. Using materials that are compatible with the fluids being sprayed helps prevent chemical reactions, corrosion, or degradation of the nozzle, ensuring longer service life and reliable performance.

Depending on the application, spray nozzles may be exposed to abrasive particles or high-velocity flows that can cause wear. Materials with high wear resistance, such as ceramic or tungsten carbide, are chosen to withstand these harsh conditions and maintain nozzle performance over time.

Spray nozzles can encounter extreme temperatures in certain applications. Materials like stainless steel or ceramic are selected for their ability to withstand high temperatures without deforming, melting, or losing their structural integrity.

Different materials have varying strength and structural properties, allowing them to handle different pressure levels. Nozzles used in high-pressure applications may require materials like stainless steel or brass to ensure they can withstand the internal forces without failure.

Material selection also takes into account factors such as cost-effectiveness and ease of manufacturing. Some materials, like plastics or aluminum, can offer lower production costs and easier processing while still meeting the required performance criteria for certain applications.

By selecting the appropriate materials for spray nozzles based on the specific requirements of the application, manufacturers can optimize nozzle performance, durability, chemical resistance, and overall efficiency.

Commonly used materials in spray nozzle manufacturing

Stainless Steel is Known for its durability, corrosion resistance, and high-temperature capabilities, stainless steel is widely used in spray nozzle manufacturing.

Brass is a popular material due to its excellent thermal conductivity and resistance to corrosion. It is often used in applications where compatibility with certain chemicals is required.

Plastics or Polymers such as polypropylene (PP) and polyvinyl chloride (PVC), are utilized in spray nozzle manufacturing due to their lightweight nature, chemical resistance, and cost-effectiveness.

Ceramic nozzles are favored for their exceptional wear resistance and high-temperature capabilities. They are commonly used in industries such as mining, steel manufacturing, and chemical processing.

Tungsten Carbide is a hard and wear-resistant material often used in applications involving abrasive liquids or high-pressure environments. It provides excellent durability and extended service life for spray nozzles.

Aluminum is a lightweight material that finds applications in spray nozzle manufacturing, particularly for low-pressure and low-temperature applications. It offers good corrosion resistance and is cost-effective.

PTFE (Polytetrafluoroethylene) is a non-stick, chemically inert material widely used in nozzle manufacturing. It is suitable for handling corrosive chemicals and is known for its low friction properties.

It’s worth noting that the choice of material depends on the specific requirements of the application, including factors like operating conditions, chemical compatibility, pressure, temperature, and desired nozzle performance.