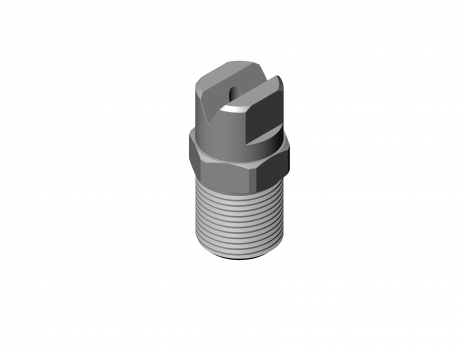

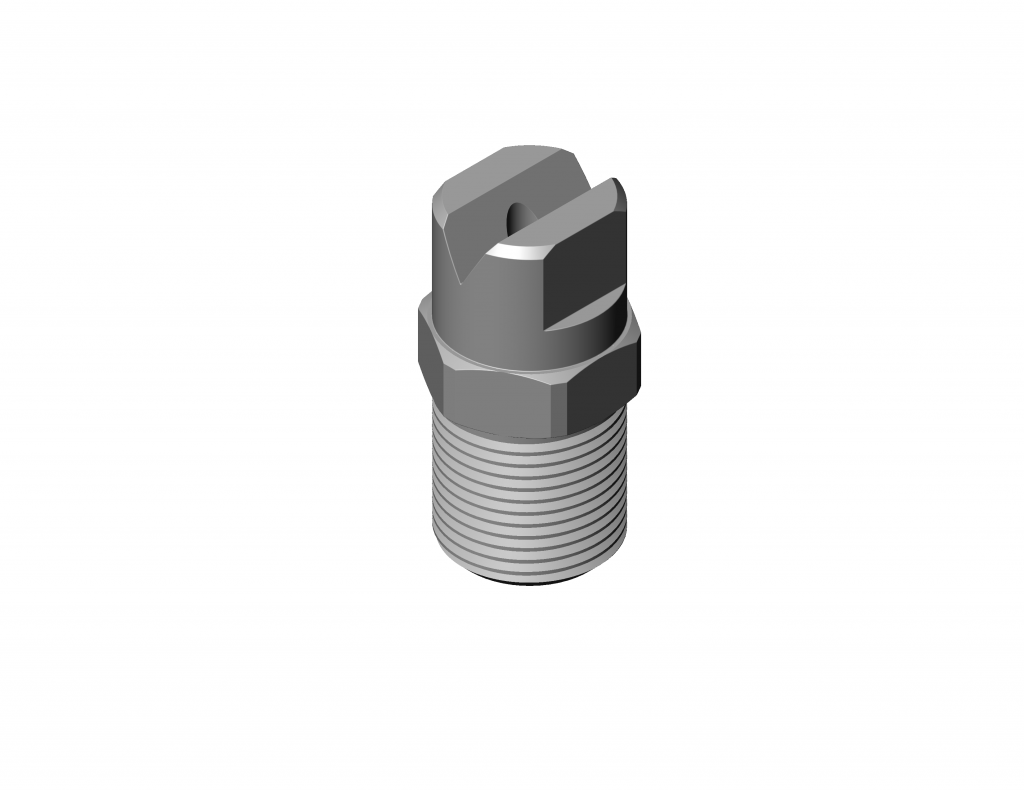

Durable and Corrosion-Resistant: Stainless Steel Spray Nozzles for Reliable Performance

Stainless steel exhibits excellent corrosion resistance properties, making it highly desirable in various applications

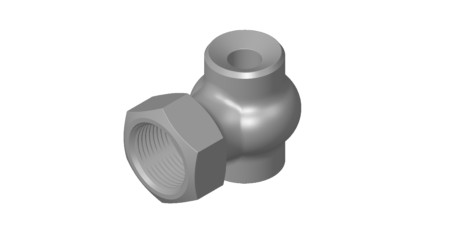

Stainless steel is a popular material used in spray nozzle manufacturing for several reasons:

Corrosion Resistance: Stainless steel is highly resistant to corrosion, making it suitable for applications involving exposure to corrosive fluids or environments. It can withstand harsh chemicals, acids, and salts without corroding or deteriorating, ensuring long-lasting performance.

Stainless steel is known for its durability and strength. It can withstand high pressures, impacts, and mechanical stresses without deforming or breaking. This makes stainless steel nozzles suitable for demanding industrial applications where reliability and longevity are essential.

Stainless steel is a non-porous material, making it easy to clean and maintain high levels of hygiene. It is often used in industries such as food and beverage, pharmaceuticals, and healthcare, where cleanliness and contamination control are critical.

Stainless steel has excellent high-temperature capabilities, allowing it to withstand elevated temperatures without losing its structural integrity. It is commonly used in applications involving hot liquids or steam.

Stainless steel has a sleek and modern appearance, making it a popular choice for applications where visual aesthetics are important, such as architectural and decorative uses.

Stainless steel comes in various grades and alloys, each with its own specific properties, making it versatile for different applications. Manufacturers can select the appropriate stainless steel grade based on factors like chemical compatibility, temperature range, and mechanical requirements

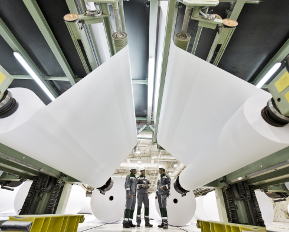

Due to its exceptional corrosion resistance, durability, and versatility, stainless steel is widely utilized in spray nozzle manufacturing across a range of industries, including agriculture, automotive, chemical processing, cleaning, cooling, and many others.