Lightweight & Versatile: Aluminium Spray Nozzles with excellent strength-to-weight ratio and corrosion resistance

The use of Aluminium in spray nozzles provides lightweight, corrosion-resistant and heat dissipation

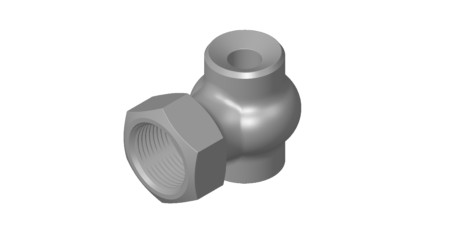

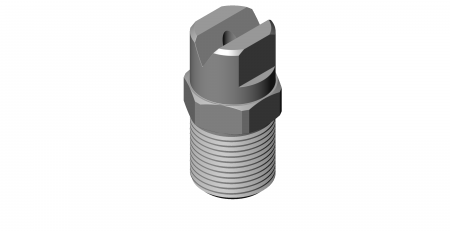

Aluminium spray nozzles are nozzles designed specifically for spraying liquids, such as water, chemicals, or other substances, using a pressurized system. These nozzles are constructed with aluminum, a lightweight and durable material that is resistant to corrosion.

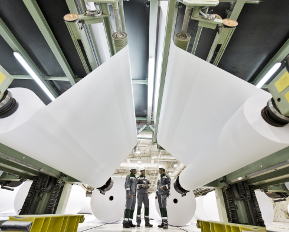

Aluminium spray nozzles are commonly used in various applications, including agriculture, gardening, industrial cleaning, firefighting, and chemical processing. They are available in different designs and configurations to suit specific spraying requirements.

The key advantages of aluminium spray nozzles include:

Aluminum is lighter than many other metals, making the nozzles easier to handle and reducing operator fatigue.

Aluminum naturally forms a protective oxide layer, which helps prevent corrosion and extends the lifespan of the nozzle, even when exposed to harsh chemicals or environments.

Aluminum is a sturdy material that can withstand demanding conditions, including high pressure and temperature.

Aluminum has good thermal conductivity, allowing heat to dissipate quickly. This property is particularly useful in applications where high-temperature liquids are sprayed.

Aluminium spray nozzles are available in various types, such as flat fan, full cone, hollow cone, and misting nozzles, allowing for different spray patterns and coverage options.

When using aluminium spray nozzles, it’s essential to consider the compatibility of the nozzle material with the liquid being sprayed. Some chemicals or aggressive substances may require alternative nozzle materials to ensure compatibility and prevent damage or chemical reactions.

It’s always advisable to refer to the manufacturer’s recommendations and guidelines for proper nozzle selection, usage, and maintenance to achieve optimal performance and longevity.