Spray Nozzles and the Industrial Manufacturing Industry

Spray nozzles are commonly used in manufacturing processes for various applications, including coating, cleaning, cooling, lubrication, and chemical reactions. They are designed to deliver a controlled spray of liquid or gas to achieve specific objectives in the production line.

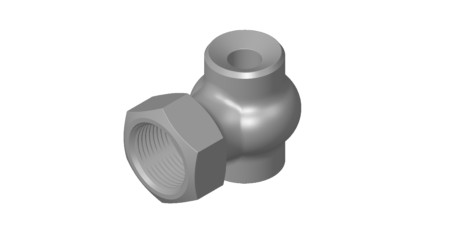

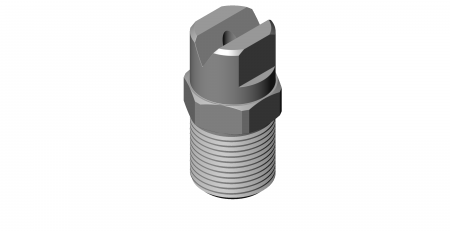

Spray nozzles come in a variety of designs to suit different applications. Some common types include flat fan nozzles, full cone nozzles, hollow cone nozzles, misting nozzles, air atomizing nozzles, and fogging nozzles. Each type has specific spray patterns and droplet sizes, allowing for precise control over the spray coverage and intensity.

Spray nozzles are typically made of materials such as stainless steel, brass, plastic, or ceramics, depending on the requirements of the application. The material choice ensures compatibility with the sprayed fluid, resistance to corrosion or chemical attack, and durability in the manufacturing environment. Nozzle construction may also include internal components like filters or orifices for further control.

The spray pattern and droplet size produced by a nozzle significantly impact its effectiveness in a manufacturing process. The spray pattern refers to the shape or coverage area of the spray, which can be flat, conical, or circular. Droplet size refers to the size of individual droplets in the spray, ranging from fine mist-like particles to larger droplets. The spray characteristics are adjusted by selecting the appropriate nozzle type and adjusting factors such as flow rate, pressure, and spray angle.

Spray nozzles require a specific flow rate and pressure to achieve the desired spray pattern and droplet size. The flow rate is the amount of liquid or gas passing through the nozzle per unit of time, typically measured in gallons per minute (GPM) or liters per minute (LPM). The pressure is the force applied to the fluid to propel it through the nozzle, usually measured in pounds per square inch (PSI) or bars. Manufacturers need to ensure the flow rate and pressure are properly controlled to achieve consistent and accurate results.

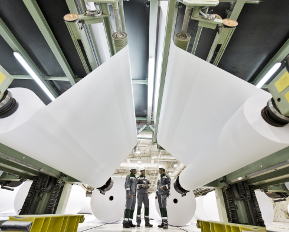

Spray nozzles find applications in various manufacturing industries. For example, in coating processes, such as painting or surface treatment, spray nozzles provide an even and uniform application of the coating material onto the target surface. In cleaning applications, they are used for high-pressure cleaning, precision cleaning, or rinsing tasks. Spray nozzles are also employed in cooling systems, lubrication processes, gas scrubbing, humidification, and many other manufacturing operations.

Proper maintenance and cleaning of spray nozzles are crucial for their optimal performance. Nozzles can get clogged or suffer from wear and tear over time, leading to reduced spray quality or blockages. Regular inspection, cleaning, and replacement of nozzles as needed are essential to ensure consistent and reliable operation.

Overall, spray nozzles play a critical role in manufacturing processes by providing controlled and efficient delivery of liquids or gases. Their versatility and precision make them indispensable tools in achieving desired product quality, process efficiency, and cost-effectiveness in a wide range of industries.