Full Cone Spray Nozzles

Full cone nozzles offer uniform spray distribution, efficient fluid utilization, and versatile applications across industries worldwide.

Nozzles are crucial components in many industries and applications, where they play a vital role in delivering fluids in the form of sprays, mists, or jets. Among the different types of nozzles available, full cone nozzles are highly versatile and widely used due to their ability to produce a uniform, circular spray pattern. This article aims to explore the characteristics, working principles, applications, and advantages of full cone nozzles.

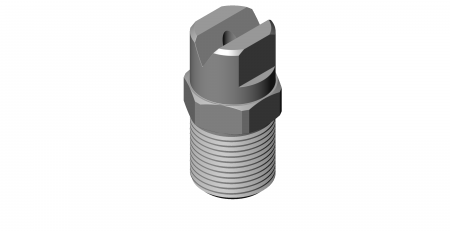

Full cone nozzles, as the name suggests, produce a complete 360-degree cone-shaped spray pattern, covering a wide area. The spray pattern is dense and evenly distributed, with small droplet sizes and a high level of spray uniformity. The droplet sizes generated by full cone nozzles can vary, ranging from fine mists to larger droplets, depending on the specific design and application requirements. The spray angle, another important characteristic, determines the coverage area and can range from narrow angles to wide angles, accommodating various spraying needs.

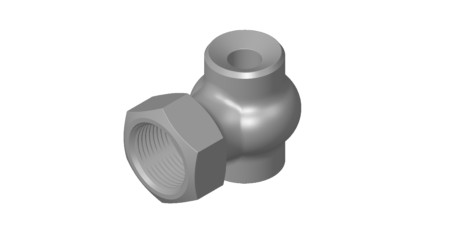

Full cone nozzles operate based on the principle of energy conversion. The fluid, typically a liquid, enters the nozzle through an inlet and passes through a swirl chamber or vane, which imparts a rotational motion to the fluid. As the fluid leaves the swirl chamber, it encounters a series of orifices arranged in a circular pattern, resulting in the formation of a cone-shaped spray. The orifices control the flow rate, droplet size, and spray angle. By adjusting the operating parameters such as pressure, flow rate, and nozzle design, the spray characteristics can be tailored to suit specific applications.

Applications of Full Cone Nozzles:

Full cone nozzles find applications in a wide range of industries and processes. Some common applications include:

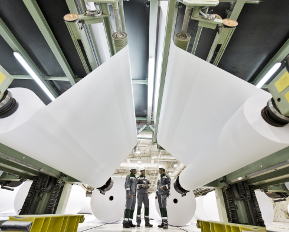

Cooling and humidification: Full cone nozzles are used for cooling and humidifying applications in industries such as air conditioning, power generation, chemical processing, and food processing. The fine mist generated by these nozzles absorbs heat and enhances the efficiency of cooling systems while providing controlled humidity levels.

Dust suppression: Full cone nozzles are employed for dust control in mining operations, construction sites, and material handling facilities. The dense spray pattern helps in effectively capturing and settling dust particles, thereby improving air quality and reducing health risks.

Cleaning and washing: Full cone nozzles are used for cleaning and washing applications in various industries, including automotive, agriculture, and manufacturing. The uniform spray pattern ensures thorough coverage, facilitating efficient cleaning of surfaces and equipment.

Fire protection: Full cone nozzles are utilized in fire suppression systems, where they disperse water or fire-retardant agents in a full cone spray pattern. The even distribution of the spray helps extinguish flames and control fire spread effectively.

Advantages of Full Cone Nozzles:

Full cone nozzles offer several advantages over other types of nozzles:

The full cone spray pattern ensures uniform coverage, eliminating any gaps or unevenness in the sprayed area.

Full cone nozzles maximize the utilization of fluids by delivering them precisely where needed, reducing waste and optimizing performance.

Full cone nozzles can be customized to meet specific requirements, offering a wide range of spray angles, flow rates, and droplet sizes.

The internal structure of full cone nozzles is designed to resist clogging, allowing for continuous operation even in demanding environments.

Full cone nozzles are generally easy to install and maintain, requiring minimal downtime and reducing overall operational costs.

Full cone spray nozzles provide efficient and reliable spray performance across various applications. Their ability to generate a uniform spray pattern, along with adjustable spray angles and droplet sizes, makes them suitable for a wide range of industries. From cooling and dust suppression to cleaning and fire protection, full cone nozzles play a vital role in enhancing productivity, improving safety, and conserving resources. With their numerous advantages and versatile capabilities, full cone nozzles continue to be an indispensable tool in fluid delivery systems worldwide.