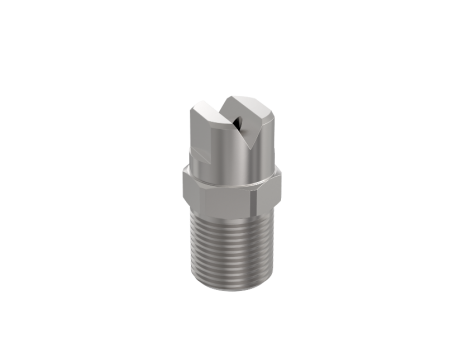

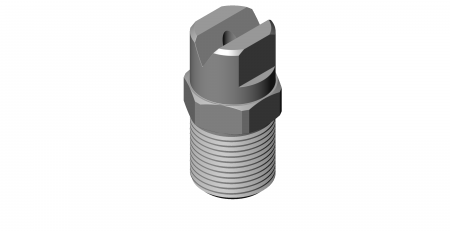

Flat Fan Spray Nozzles

Flat fan spray nozzles provide uniform, wide coverage for applications such as cleaning, coating, cooling, and irrigation.

Flat fan spray nozzles are integral components used in a wide range of industries and applications. Their ability to deliver a uniform and wide spray pattern makes them highly versatile and valuable tools for tasks such as cleaning, coating, cooling, and irrigation. In this comprehensive guide, we will explore the working principle, design features, advantages, and applications of flat fan spray nozzles in detail.

Flat fan spray nozzles generate a flat and fan-shaped spray pattern by utilizing a specific design. The nozzle typically consists of a narrow orifice and a deflection surface. When a liquid or gas flows through the orifice, it strikes the deflection surface, causing it to spread out in a fan-shaped pattern. The angle of the fan spray can be adjusted by altering the design of the deflection surface or by using interchangeable caps with different angles. This working principle ensures that the spray pattern is evenly distributed from edge to edge, providing consistent coverage over the target area.

Flat fan spray nozzles incorporate various design features to optimize their performance. Some of the key design elements include:

The size and shape of the orifice directly influence the flow rate and velocity of the liquid or gas passing through the nozzle. Different applications may require specific orifice sizes to achieve the desired flow rate and spray characteristics.

The deflection surface plays a crucial role in shaping the spray pattern. It is designed to distribute the liquid or gas evenly and efficiently across the target area. The surface may have specific contours or angles to control the width and coverage of the fan spray pattern.

Flat fan spray nozzles are typically constructed from materials such as stainless steel, brass, plastic, or ceramic. The choice of material depends on factors like chemical compatibility, durability, and resistance to corrosion or wear in the specific application environment.

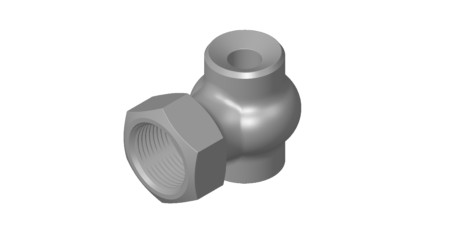

Many flat fan spray nozzles offer adjustability in terms of the spray angle. This feature allows users to customize the width of the fan spray pattern to suit their specific requirements. The adjustability can be achieved by using interchangeable caps or by designing the deflection surface with variable angles.

Flat fan spray nozzles offer numerous advantages that contribute to their widespread use in various industries. Some of the key advantages include:

Flat fan spray nozzles are capable of delivering a wide spray pattern, allowing for efficient and quick spraying of large surfaces. This feature makes them ideal for applications such as cleaning conveyor belts, spraying pesticides in agriculture, or applying coatings on wide substrates.

The design of flat fan spray nozzles results in a high impact force, which is beneficial for cleaning or removing debris from surfaces. The forceful spray helps to dislodge dirt, grime, or contaminants effectively, making them suitable for cleaning applications.

One of the essential advantages of flat fan spray nozzles is the uniformity of the spray distribution. The spray pattern is evenly distributed from edge to edge, ensuring consistent coverage over the target area. This uniformity is critical in applications where precise and uniform spraying is required for optimal results.

Low Drift Potential: Flat fan spray nozzles have a low drift potential, meaning that the majority of the spray is directed towards the target area. This reduces wastage and minimizes environmental contamination. It is particularly important in applications where precise application of chemicals is required to avoid negative impacts on surrounding areas.

Compatibility with Various Fluids

Flat fan spray nozzles are compatible with a wide range of fluids, including water, chemicals, oils, and solvents. This versatility allows them to be used in diverse industries, from agriculture and manufacturing to food processing and mining.

Materials Used in Spray Nozzles

The material of the spray nozzle affects its durability, resistance to corrosion, and suitability for different liquids. Common materials include:

Brass: Used for general-purpose applications where corrosion resistance is not a major concern. Brass nozzles are cost-effective and suitable for use with water and non-corrosive chemicals.

Stainless Steel: Offers excellent corrosion resistance, making it suitable for harsh environments and use with aggressive chemicals. Stainless steel is commonly used in food processing, chemical manufacturing, and mining applications.

Plastic including Polypropylene, PVC, Teflon: Lightweight and resistant to many chemicals, plastic nozzles are often used in agricultural applications and areas where the liquid being sprayed is not abrasive.

Ceramic: Extremely resistant to wear and chemical corrosion, ceramic nozzles are ideal for abrasive materials like slurries or for use in environments with high temperatures.

Tungsten Carbide: Known for its hardness and wear resistance, carbide nozzles are used in high-pressure applications and with abrasive materials like sand or slurry in mining and drilling operations

Each material is chosen based on the specific needs of the application, including factors such as the type of liquid, operating environment, pressure requirements, and expected lifespan of the nozzle.

Applications of Flat Fan Spray Nozzles

Flat fan spray nozzles find applications in numerous industries and tasks due to their versatility and performance. Some common applications include:

Flat fan spray nozzles are extensively used in agriculture for crop spraying. They ensure even distribution of fertilizers, pesticides, and herbicides, promoting crop health and maximizing yield. Additionally, they are employed in irrigation systems to provide efficient water distribution across fields.

Flat fan spray nozzles are widely used in cleaning applications, such as car wash systems, industrial equipment cleaning, and sanitation processes. The high impact force and uniform spray distribution make them effective in removing dirt, grime, and other contaminants from surfaces.

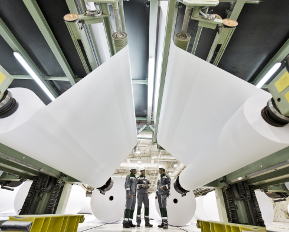

In manufacturing and finishing processes, flat fan spray nozzles are used for applying coatings, paints, adhesives, or lubricants onto various products. The wide coverage area and uniform spray distribution ensure consistent coating thickness and quality.

Flat fan spray nozzles are employed in cooling systems to lower temperatures in industrial processes or outdoor areas. They are used for evaporative cooling, dust suppression, and temperature regulation in industries such as power generation, steel production, and outdoor cooling systems.

Flat fan spray nozzles play a crucial role in the food processing industry. They are used for cleaning and sanitizing food processing equipment, as well as for applying coatings, glazes, or flavorings on food products.

In mining and construction operations, flat fan spray nozzles are utilized for dust suppression. By generating a fine mist of water or specialized chemicals, they help control airborne dust particles, enhancing worker safety and minimizing environmental impact.

Flat fan spray nozzles are versatile and essential tools in numerous industries and applications. Their ability to deliver a uniform and wide spray pattern, combined with advantages such as wide coverage area, high impact force, low drift potential, and compatibility with various fluids, makes them valuable assets. Whether it’s for cleaning, coating, cooling, or irrigation, flat fan spray nozzles provide efficient and reliable performance, ensuring consistent results in diverse applications. Their versatility and effectiveness contribute to increased productivity, improved quality, and enhanced safety across a wide range of industries.