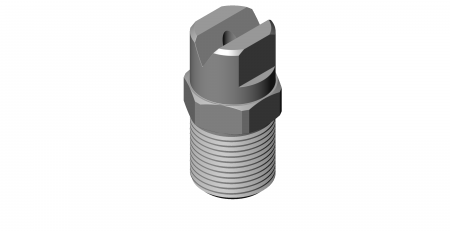

Durable and Chemical-Resistant: Plastic or Polymer Spray Nozzles are built to last

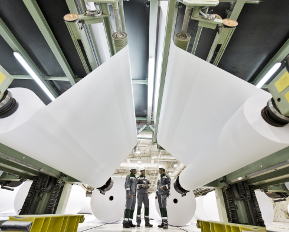

Polymers are widely used in manufacturing due to their versatility, ease of processing, and desirable properties.

Spray nozzles are critical components used in a variety of industries for spraying liquids, gases, or a combination of both. When it comes to the materials used in spray nozzle construction, polymers are commonly employed due to their favorable properties. Here are some polymer materials frequently used in spray nozzles:

Polyvinyl Chloride (PVC) is a popular polymer choice for spray nozzles due to its affordability, corrosion resistance, and versatility. It is often used in applications where chemical resistance is required.

Polypropylene (PP) is a thermoplastic polymer known for its excellent chemical resistance and high-temperature stability. Spray nozzles made from PP are widely used in chemical processing, agriculture, and water treatment applications.

Polyethylene (PE) is another thermoplastic polymer that offers good chemical resistance and flexibility. It is often used in spray nozzles for agricultural spraying, lawn care, and general-purpose spraying.

Polytetrafluoroethylene (PTFE) is a high-performance polymer known for its exceptional chemical resistance and low friction properties. It is commonly used in spray nozzles for applications involving aggressive chemicals, such as in the chemical industry or surface treatment processes.

Acetal (Polyoxymethylene, POM) is a strong and rigid polymer with good dimensional stability. Spray nozzles made from acetal are suitable for applications requiring precision and resistance to wear and tear.

Polyvinylidene Fluoride (PVDF) is a fluoropolymer known for its excellent chemical resistance, high-temperature resistance, and UV stability. Spray nozzles made from PVDF are commonly used in the chemical industry, water treatment, and harsh environmental conditions.

Nylon is a versatile polymer with good mechanical strength and resistance to abrasion. It is used in spray nozzles for various applications, including car washes, cooling systems, and industrial cleaning.

These polymer materials offer a combination of properties such as chemical resistance, mechanical strength, temperature resistance, and affordability, making them suitable for different spray nozzle applications. The choice of polymer depends on the specific requirements of the spraying process, including the type of liquid or gas being sprayed, operating conditions, and durability needed.