Pumps: The Lifeline of Fluid Management in Modern Engineering Systems

Pumps are indispensable devices that have revolutionized modern engineering systems across multiple industries.

Pumps serve as the lifeline of fluid management in numerous industries, enabling the movement and control of liquids with efficiency and precision. From small-scale applications in household systems to large-scale industrial processes, pumps are essential devices that play a critical role in fluid transportation. This essay delves into the significance of pumps, their various types, working principles, and applications across diverse fields.A pump is a mechanical device designed to transfer fluids from one location to another. Its primary function is to generate flow and overcome resistance, enabling the movement of liquids through a system. Pumps are used to transport a wide range of fluids, including water, oil, chemicals, and gases, in industries such as agriculture, manufacturing, energy, and construction.

Pumps come in various types, each tailored to specific applications and fluid characteristics. Understanding these types is crucial for selecting the appropriate pump for a given task.

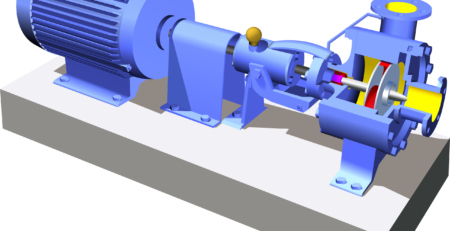

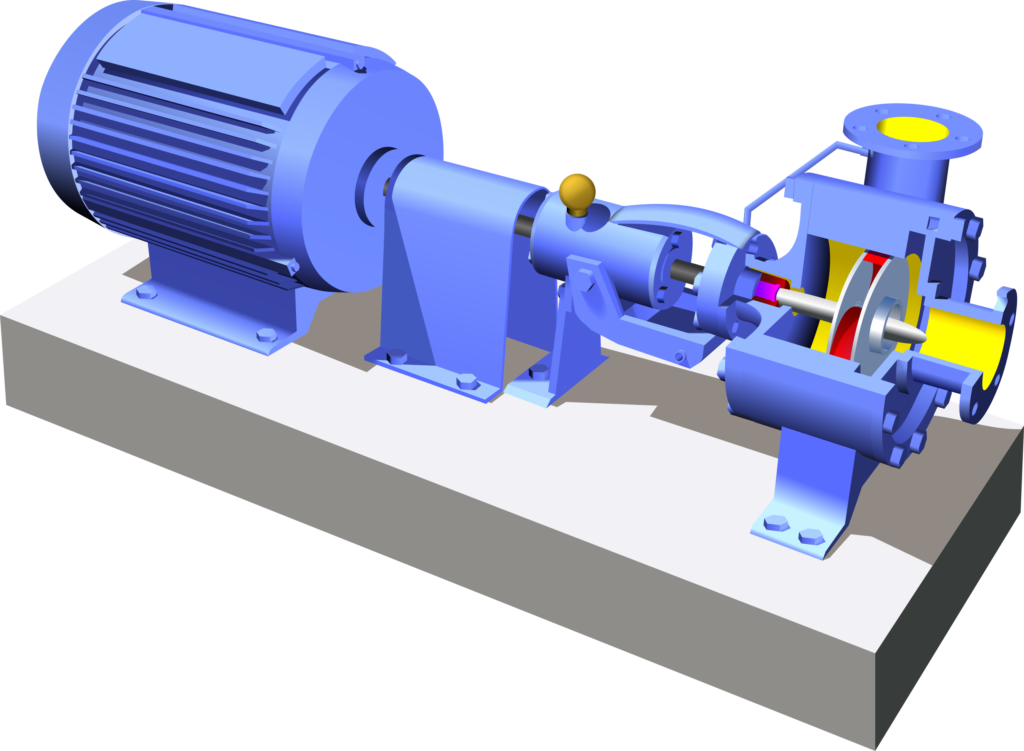

Centrifugal Pumps pumps employ centrifugal force to increase the velocity of the fluid and convert it into pressure energy. They are widely used due to their high flow rates, low maintenance requirements, and relative simplicity. Centrifugal pumps find applications in HVAC systems, wastewater treatment plants, irrigation systems, and water supply networks.

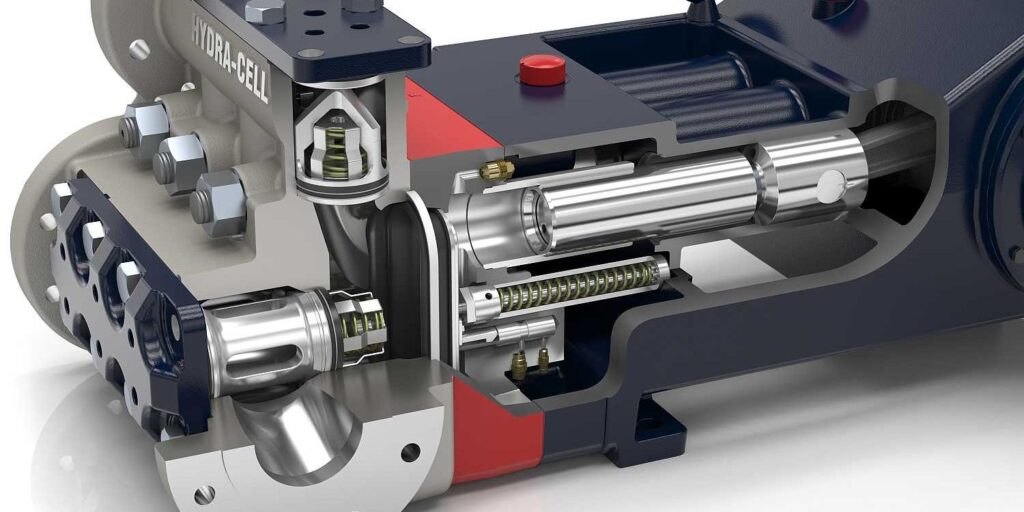

Positive Displacement Pumps: Unlike centrifugal pumps, positive displacement pumps transfer fluids by trapping and displacing a fixed volume of liquid. They offer precise control over flow rates and are suitable for handling viscous fluids or applications requiring high pressure. Examples of positive displacement pumps include reciprocating pumps, rotary pumps, and diaphragm pumps. They are commonly used in oil and gas, pharmaceuticals, food processing, and chemical industries.

Axial flow pumps operate by creating lift and axial flow through rotating blades. These pumps are efficient at moving large volumes of fluid but are generally limited to low-pressure applications. They find extensive use in flood control, sewage treatment, water circulation systems, and irrigation projects.

Designed to operate underwater, submersible pumps are widely employed in groundwater extraction, drainage systems, and sewage treatment. These pumps are compact, self-priming, and offer high efficiency in moving fluids from submerged depths.

Vacuum pumps remove gases or create low-pressure environments by extracting air from a closed system. They are essential in processes such as vacuum distillation, freeze-drying, and semiconductor manufacturing.

Understanding the working principles of pumps is crucial for comprehending their functionality and selecting the appropriate type for a given application. Generally, pumps operate based on one of the following principles:

Dynamic (Kinetic) centrifugal pumps use a rotating impeller to impart kinetic energy to the fluid. The centrifugal force created by the impeller’s rotation converts the kinetic energy into pressure energy, enabling the fluid’s movement.

Positive displacement pumps transfer fluids by periodically trapping a fixed volume and then forcing it into the discharge pipe. This principle relies on the creation of a pressure difference across the pump’s inlet and outlet.

Electromagnetic pumps utilize magnetic fields to induce the movement of conductive fluids. They are often used in applications involving corrosive fluids, hazardous environments, or precise control of flow rates.

Pneumatic pumps use compressed air or gas to displace the fluid. These pumps find applications in various industries, including chemicals, pharmaceuticals, and food processing.

Pumps find extensive applications across a broad range of industries and systems, playing a crucial role in enabling various processes.

Water Supply and Treatment Pumps are vital in delivering clean water to communities, supplying water to high-rise buildings, and ensuring efficient water treatment processes. They help maintain water pressure, transfer water between reservoirs, and facilitate the distribution of treated water.

In manufacturing plants, pumps are used to transfer chemicals, lubricants, and other liquids required for production. They aid in cooling systems, hydraulic power, material handling processes, and circulation in industrial machinery. Pumps are also crucial in the oil and gas industry for extracting, refining, and transporting petroleum products.

Pumps play a key role in generating energy by transferring fluids in power plants. In hydroelectric power plants, pumps help transport water to drive turbines, while in thermal power plants, pumps facilitate the circulation of steam. Pumps also support geothermal and nuclear power generation.

HVAC or Heating, Ventilation, and Air Conditioning systems rely on pumps to circulate coolants, such as refrigerants, throughout buildings. They assist in maintaining comfortable temperatures, controlling humidity levels, and ensuring efficient heat exchange in residential, commercial, and industrial spaces.

Environmental Systems Pumps are crucial in wastewater treatment facilities, where they aid in moving sewage through treatment processes and ensuring the proper disposal of effluent. They are also used in drainage systems, preventing flooding in urban areas during heavy rainfall.

Transportation and Maritime Industry Pumps are utilized in ships, submarines, and offshore platforms for ballasting, firefighting, fuel transfer, and cargo loading/unloading. They enable the smooth operation of maritime vessels, ensuring their safety and efficiency.

Agriculture and Irrigation Pumps are extensively employed in agriculture for irrigation purposes, allowing farmers to efficiently deliver water to crops. They are also used for dewatering, drainage, and transferring fertilizers and pesticides in agricultural systems.Pumps are indispensable devices that revolutionize fluid management across a wide range of industries and applications. Their ability to transfer fluids efficiently and reliably makes them vital components in systems ranging from water supply and treatment to manufacturing processes and energy production. As technology advances, pumps continue to evolve, offering enhanced performance, increased energy efficiency, and improved reliability. The selection of the appropriate pump type and understanding its working principles are crucial for optimizing system performance, minimizing energy consumption, and ensuring the smooth operation of various engineering processes. Pumps will remain an essential component of modern engineering systems, serving as the backbone of fluid transportation and control in the industrialized world.