Eductors & Tank Agitation

Eductors, also known as mixing nozzles or jet agitators, are commonly used in tank agitation applications to enhance the mixing of liquids or to facilitate the incorporation of additives or chemicals into a bulk fluid. These devices work based on the principle of fluid dynamics, utilizing the energy from a high-velocity fluid stream to create turbulence and promote mixing within a tank or container.

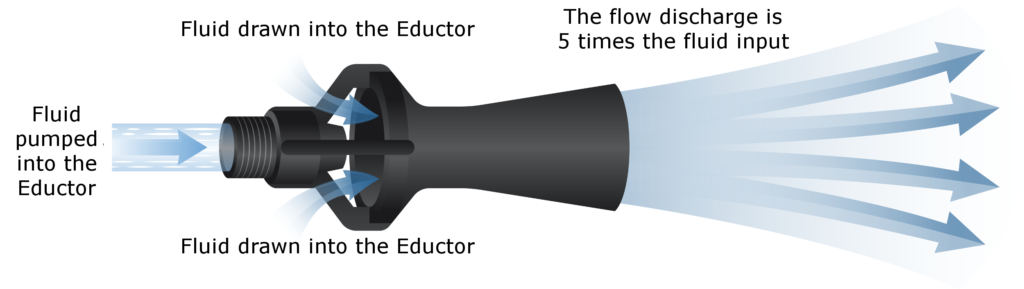

Eductors consist of a nozzle orifice that creates a high-velocity jet of fluid (often water) and a suction chamber or venturi that draws in additional fluids or additives. As the high-velocity jet exits the nozzle, it creates a low-pressure zone in the suction chamber, causing additional fluids to be entrained or drawn into the mixing process.

Eductors are designed to maximize the mixing efficiency within a tank. The high-velocity jet creates turbulence and shear forces that promote thorough mixing of the fluids. The entrainment of additives or chemicals from the suction chamber ensures their rapid and uniform distribution within the tank.

Eductors come in various designs and configurations to suit different tank sizes and mixing requirements. The size and shape of the nozzle, as well as the dimensions of the suction chamber, can vary depending on factors such as flow rates, viscosity of the fluids, and desired mixing intensity.

Eductors are typically installed in tanks by mounting them at specific locations, such as the tank sidewall or at the bottom of the tank. The installation position depends on the desired flow pattern and mixing goals. Multiple eductors can be used in larger tanks or containers to ensure adequate mixing coverage.

Eductors find applications in various industries, including agriculture, water treatment, chemical processing, and food and beverage. In agriculture, they are commonly used for tank mixing pesticides, fertilizers, or other agricultural chemicals, ensuring proper dispersion and homogeneity of the mixture.

When using eductors, it is important to consider factors such as the viscosity and density of the fluids being mixed, the flow rate and pressure of the motive fluid (often water), and the desired mixing intensity. Proper sizing and selection of eductors, as well as understanding the fluid dynamics within the tank, are essential for achieving effective mixing results.

As with any equipment or mixing or agitation process, it is recommended to consult with manufacturers, experts, or professionals in the specific industry or application to ensure proper selection, installation, and operation of eductors for tank mixing purposes.